From fuel to bilge, there’s a Trident marine Hose to meet each of your on board needs.

|

NAME﹣PART#﹣IMAGE |

DESCRIPTION |

I.D. SIZE |

| TRIDENT A2 FUEL LINE & FILL – USCG · ISO · SAE · NMMA · LLOYD’S · CE 327/328

|

Trident A2 Marine Fuel Hose (Fill and Vent plus Diesel Distribution) meets newest ABYC H-24 and H-33, SAE J1527, SAE J30R6, ISO 7840 A2, USCG Type A2; and is NMMA Type Accepted, CE Certified and Lloyds Approved, for all marine fuels including gasoline, alcohol blends, diesel and bio-diesel. Built with thick wall, smooth cover and wire helix between 2 ply reinforcement for extra service life and bend-ability. Formulated for Max resistance to fuels, fire, heat, cold, ozone, aging and permeation. #328 Series is same as #327, but without wire helix. |

3/4” to 2-3/8” |

| TRIDENT A1-15 FUEL LINE – USCG · ISO · SAE · NMMA · ABYC · CE · EPA ·CARB 365

|

Trident Barrier Lined “Low Perm” A1-15 Marine Fuel Hose (Distribution, Return, Vent and Transfer) for all marine fuels including gasoline, alcohol blends (CE-10), diesel and bio-diesel. Meets newest ABYC H-24 and H-33, SAE J1527, CARB and EPA “A1-15” and USCG Type A1, ISO 7840 A1 standards and requirements, and is NMMA type Accepted and CE Certified. Built with 2 spiral reinforcement and unique “Perm Barrier Liner” on inside surface of tube. Formulated for Max resistance to fuels, fire, heat, cold, ozone, aging and permeation. New EPA Certified and CARB Compliant. |

1/4” to 3/4” |

| TRIDENT B1-15 FUEL LINE – USCG · SAE · NMMA · ABYC · CE · EPA ·CARB 305

|

Trident Barrier Lined “Low Perm” B1-15 Marine Outboard Rubber Fuel Line Hose for all marine fuels including gasoline, alcohol blends (CE-10), diesel and bio-diesel. Meets newest ABYC H-24, SAE J1527, USCG, ISO 8469, CARB and EPA standards; and NMMA Type Accepted, CE Certified and EPA Certified. Built with 2 spiral reinforcement, New Ultra Low Perm Barrier Liner, and Light Grey CPE Cover. Formulated for Max resistance to fuels, heat, cold, ozone, abrasion, aging and permeation. New EPA Certificate of Conformity and CARB Executive Order. |

1/4” 5/6” 3/8” |

| TRIDENT FIEX MATINE WET EXHAUST & WATER (SAE J2006 & LLOYD’S) 250

|

Trident Flex wet exhaust hose for longer bent connections. In smallerI.D.’s for engine intake, critical water, drain, scupper bilge & sanitation uses. Extra heavy tube and cover with wire helix between 2 ply reinforcement provides excellent flexibility and bend radius. Resists heat, ozone, exhaust, sani chemicals, panting and collapse. Exceeds (SAE J2006-R2, and ABYC & NMMA P-1 exhaust standards). Lloyd’s Registry Type Approved Cert. 02/00029. Black High Temp EDPM Rubber 280°F (138°C) Max.** |

1/2” to 12” |

| TRIDENT SILICONS MARINE WET EXHAUST & WATER-SAE · ISO · LLOYD’S 202V/202X

|

Trident Silicone Marine Wet Exhaust & Water-Coolant Hose is the ultimate in extra thick soft wall silicone quality with very high temp. performance and extra long service life. Exceeds SAE J2006-R1, ISO 13363-1B, Lloyd’ Registry Type Approved, and ABYC & NMMA P-1 exhaust standards and is Lloyd’s Approved. #202V Glossy Blue “Very Hi Temp” has 4-6 ply polyester reinforcement and 350°F (177°C) Max. #202X Glossy Red “Xtra Hi Temp” has 4 ply Nomex® reinforcement, and 500°F (260°C) Max. Used world wide on premium boats, yachts and special service vessels. It has become the super yacht standard. See Trident Marine Wet Exhaust System Catalog.** |

1” to 18” |

| TRIDENT SILICONS & RUBBER WET EXHAUST & BELLOWS (SAE J2006 & LLOYD’S)

|

Trident Silicone & Rubber Elbows & Hump Hose Bellows provide the ultimate flexible connectors for Marine Wet Exhaust Systems. They offer much greater tolerance to heat, misalignment, engine movement & vibration, with significant savings in cost, parts, labor and space. Highest max. continuous operating temps – Molded Black Hi Temp EPDM Rubber 280°F (138°C), Blue Very Hi Temp. Silicone 350°F (177°C), Red Xtra Hi Temp. Silicone 500°F (260°C). Silicone (Blue and Red), also available w/ 4 to 6 ply reinforcement. All exceed (SAE J2006-R3, and ABYC & NMMA P1) Std. See Marine Wet Exhaust Systems Catalog.** |

1-1/2” to 18” |

| TRIDENT SILICONS & RUBBER HEATER HOSE (SAE J20R3) 130/131V

|

131V Ultimate Silicone heater hose – Very Hi Temp Blue with Red Tube provides much greater Temp. range and service life than standard EPDM rubber #130 Heater Hose. Both are 2 spiral polyesterreinforced with similar working pressure for engine coolant water, A/C and other mid-press water applications. 131V (VHT-Blue), 45 to 75 PSI (0.31 to 0.52 Mpa) WP 350°F (177°C) SAE J20R3, Class 1 & J20 P3. 7 Year Warranty.#130 (Standard Black) 50 PSI (0.34 Mpa) W.P. 212°F (100° C) SAE J20R3. 2 Year Warranty. |

1/2” to 3/4” |

| TRIDENT SANI SHELD SANITATION HOSE 102/101

|

Premium Sanitation Hose for all head & holding tank connections. Extra thick tube & cover is specially formulated Black or White EPDM Rubber for Max. Resistance to Odor Permeation and winterizing with antifreeze. With wire helix between 2 ply reinforcement this hose has excellent bend radius, flexibility, and fitting acceptance and retention. This makes for easy installations with no heat gun or lubricant necessary. It’s Legendary odor-free performance is the best on the market. Self draining installations still recommended. Not for potable water. |

1” 1-1/2” 1-7/8” |

| TRIDENT VAC X.H.D. SANITATION HOSE – FDA 148

|

Extra heavy duty sanitation hose of smooth white vinyl. Specially compounded to provide resistance to odor permeation and (FDA) potable water fill. Also for critical bilge, drain scupper, live well, etc. Hard PVC helix gives good flexibility and bend radius. No cuffs required.* Don’t use with alcohols, anti freeze, petro-chemicals or solvents. Self draining installations are necessary for odor free service. To be used in open ended pressurized, suction, and discharge applications at ambient temperatures. +10° to +120° F (-12° to +49°C). CA prop 65 Compliant. |

5/8” to 1-1/2” |

| TRIDENT HD REINFORCED PVC – FDA 161

|

Heavy duty non-toxic FDA compounded PVC with nylon reinforcement. For pressurized drinking water systems and many other uses. Resists odor, taste and up to 250 PSI/WP (depending on I.D. size) @ 70°F (21°C). For cold and hot tap water. Operating temperatures +20° to +150°F. (-7° to +66°C) Good flexibility and bend radius.* CA prop 65 Compliant. |

1/4” to 1-1/2” |

| TRIDENT REINFORCED PVC – FDA 164/12

|

Nylon reinforced. FDA compounded PVC for pressurized drinking water systems, etc. No taste or odor. #164 “Cold Water”. Max W.P. depending on I.D. size @ 70°F (21°C): #162=175 PSI (1.21Mpa), #164=150 PSI (1.03 Mpa). Operating temperatures +20° to +150° F (-7° to +66°C). NOT RECOMMENDED FOR BELOW WATERLINE THRU-HULL CONNECTIONS. CA prop 65 Compliant. |

3/8” to 1” |

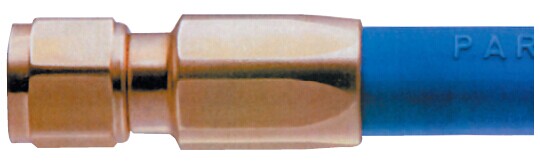

| PARKER COMMERCIAL FUEL HOSE & FITTINGS-USCG A1 · SAE J1942 · ISO · CE 221FR

|

Nylon reinforced. FDA compounded PVC for pressurized drinking water systems, etc. No taste or odor. #164 “Cold Water”. Max W.P. depending on I.D. size @ 70°F (21°C): #162=175 PSI (1.21Mpa), #164=150 PSI (1.03 Mpa). Operating temperatures +20° to +150° F (-7° to +66°C). NOT RECOMMENDED FOR BELOW WATERLINE THRU-HULL CONNECTIONS. CA prop 65Compliant. |

1/4” 5/16” 13/32” 1/2” 5/8” 7/8”

|